Factory Z119 (hereafter the Factory), under the Air Defence - Air Force Service, is a strategic-level technical support facility tasked with repairing and upgrading various types of radar systems (including the latest new-generation systems) for the Service as well as other services and arms of the Vietnam People’s Army (VPA). In addition, the Factory is responsible for restoring and manufacturing spare parts and technical materials to meet its own repair demands and the operational needs of other units across the VPA.

|

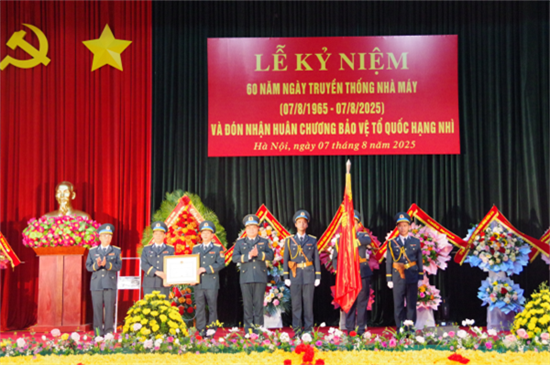

| The Factory was honoured with Second-Class Fatherland Protection Order in 2025 |

This is both an honour and a particularly demanding task, as the volume of equipment requiring repair has continued to increase, with a wide range of types manufactured by different countries. Technical procedures are extremely stringent and complex, requiring high precision, while replacement materials and components remain scarce. Meanwhile, certain enabling factors for task execution at the Factory have yet to keep pace with the rapid development of science and technology and the growing operational requirements. In response, the Factory’s Party Committee and Directorate have implemented a range of synchronous and effective measures to continuously enhance the capacity, quality, and efficiency of repairing and manufacturing new-generation weapons and equipment, thereby meeting both immediate and long-term task requirements.

First of all, the Factory has focused on building and developing its human resources, particularly high-quality personnel. A defining characteristic of new-generation weapons and equipment is their high scientific and technological content with the integration of numerous advanced technical and tactical features and modern technologies. Therefore, mastering, operating, and repairing such systems require a contingent of cadres and technical employees with profound expertise and technological proficiency. With this awareness, the Factory’s Party Committee and Directorate have proactively streamlined the organisational structure in an efficient manner, ensuring alignment with the specific requirements of assigned tasks. Relevant functional offices have been directed to develop and refine a system of standards for organisational structure, job positions, and professional qualifications, serving as the unified basis for personnel management and utilisation.

The Factory has regularly reviewed and accurately assessed its cadres and technical employees, thereby formulating long-term development plans to build a solid pool of qualified personnel. It ensures that the right people are assigned to the right jobs in line with their professional expertise so as to maximise individual capabilities and strengths. Alongside a strong emphasis on training and fostering young engineers and skilled technicians to ensure continuity and balanced age structures across specialised fields, the Factory has selected and created favourable conditions for highly qualified technical personnel to participate in technology transfer training courses and pursue further education at training institutions both inside and outside the VPA. At the same time, due regard has been paid to proactively cooperating with the Military Technical Academy, the Military Industry and Telecommunications Group, and the Air Defence - Air Force Technical Institute in organising intensive training programmes on maintenance and repair technologies for new-generation radar systems, such as new technology theories in the fields of ultra-high frequency (UHF), digital technology, and precision mechanics, practising measurement and testing techniques, mechanical design and manufacturing techniques, and high-frequency amplifier design and manufacturing techniques as well as FPGA programming training, among others.

|

| Maintaining and repairing technical equipment at a workshop |

Meanwhile, the Factory has attached significance to selecting highly skilled and experienced cadres and technical employees to form instructor groups in charge of both directly participating in repair and manufacturing activities and providing training, mentoring, and experience sharing. This aims to step by step improve the professional competence, craftsmanship, and capacity of its workforce to master and repair new military hardware and equipment. Concurrently, the Factory has created favourable conditions and incentives for cadres, workers, and employees to pursue self-study, self-research, and self-improvement in order to meet their task requirements. Notably, it has boldly entrusted young cadres and engineers with difficult and important tasks, regarding this as a real test of their mettle. This serves as a solid basis for personnel planning and the appointment of commanders at all levels. Consideration has been given to building a democratic, equitable working environment, while policies and support measures for military families have been effectively implemented, thus enabling cadres and technical personnel to work with peace of mind, remain committed in the long term, and devote themselves to the Factory’s development. Thanks to these comprehensive, scientific, and persistent solutions, when it comes to the Factory’s workforce, 100% of its cadres hold university degrees or higher (with over 50% possessing master’s or doctoral degrees), and more than 95% of its workers are professionally trained at intermediate or senior skilled levels. This constitutes a crucial foundation and prerequisite for the Factory to master and repair new-generation weapons and equipment and to successfully fulfil all assigned tasks.

Alongside improvements in human resource quality, the Factory has concentrated on in-depth technological investment and the modernisation of equipment, with the objective of achieving self-reliance in repairing, restoring, and manufacturing 100% of components and materials for successive generations of radar systems across the Service and the entire VPA. To this end, it has proactively given advice to higher echelons on upgrading infrastructure and procuring equipment and technological lines in a dual-use, modern fashion, adopting a “leapfrogging” approach to meet the requirements of sustainable development. In recent years, a number of key projects and schemes have been synchronously and effectively conducted, including “Investment in new-generation radar repair technologies” project (phase 2 and phase 3), Project 324-KT on technical support for weapons and equipment, and the project on “Enhancing capacity for product quality analysis, inspection, and assessment in the production and repair of technical equipment and materials”, making a new breakthrough in technological capability and technical support proficiency.

|

| P37 radar system installed by the Factory |

Besides, the Factory has paid due attention to the comprehensive upgrading and renovation of workshop facilities to meet the increasingly stringent requirements of repairing and maintaining weapons and technical equipment, particularly new-generation systems. To date, major infrastructure investment items have been completed and are yielding tangible results, with shortened timelines, reduced labour intensity, and markedly improved repair capacity and quality. Each year, the Factory is capable of conducting medium-level and major overhauls on between 25 and 30 radar systems of various types, including 10 to 12 sets of new-generation equipment.

At present, units across the entire VPA in general, and the Service in particular, are operating a wide range of radar systems and equipment. It is impossible for many of these systems to be repaired and maintained domestically, necessitating overseas servicing that is both time-consuming and costly. To address this challenge, the Factory has proactively intensified research efforts to master repair technologies for new-generation radar systems, while actively applying research outcomes to the design and manufacture of specialised measurement and testing devices that directly support the repair and restoration of assigned weapons and equipment. To ensure effectiveness, it has directed specialised agencies to conduct in-depth research and design of hardware schematic systems, gradually establishing a set of “standard parameters” as the basis for standardising repair procedures. Importance has been attached to accelerating the application of modern technologies in analysis and the development of comprehensive technical documentation systems, overcoming shortages of original technical manuals, and creating a solid foundation for mastering new-generation equipment.

At the same time, the Factory has stepped up scientific research, translation, and compilation of technical documentation to serve training, production, repair, and operational guidance for new types of technical equipment. In recent years, the Factory’s cadres and engineers have successfully researched and mastered repair technologies for numerous modern weapon and equipment systems. Notable achievements include the research, design, and manufacture of a pair of standard radio beacons for military aircraft landings, equivalent in performance to Russia’s PRMG-76, which won Second Prize at VIFOTEC Awards 2025, as well as artillery meteorological radars, among others. As a result, alongside the operation, mastery, and major overhaul of “P-generation” radar systems, the Factory has acquired sufficient capability to conduct medium-level repairs on many new-generation radar stations, such as P-18M, 96L6E, Kolchuga, VRS-2DM, as well as new-generation interrogator systems (76E6P, 71E6P, 1L24). These achievements have made an important contribution to enhancing technical support capacity for units of the Service and the entire VPA.

Repairing and restoring new-generation weapons and equipment is a complex task, particularly when the procurement of materials and components from abroad faces significant difficulties due to objective factors. In response, the Factory has concentrated on intensifying research, design, manufacture, improvement, and localisation of materials and components, gradually enhancing technical self-reliance and establishing a solid foundation for its core task of repairing and maintaining weapons and equipment. In line with its practical task requirements, the Factory has proactively designed, tested, and progressively refined production lines and technological processes in a standardised and synchronised manner, meeting the requirements of mass production and long-term stability. At the same time, it has directed the Technical Department to closely cooperate with functional bodies in developing focused and targeted scientific research plans, closely linking research activities with the technical support requirements of each specific type of weapons and equipment. To maximise effectiveness, the Factory has selected a contingent of technically proficient and highly skilled personnel to form specialised research groups in key areas, such as electronic circuit engineering, automatic control, software programming, and systems integration. On this basis, great value has been attached to proactively calculating and allocating sufficient funding, materials, and equipment, and selecting high-quality weapon and equipment models as research and testing subjects. Through this process, technical solutions and production procedures have been progressively refined to suit the Factory’s practical conditions. With this correct and steady approach, the Factory has now mastered the technology and manufactured more than 300 categories of replacement components and materials for radar repair, over 60 per cent of which are for new-generation systems. This represents clear evidence of a significant transition from “passive support” to “self-reliance” in technical assurance, laying a firm foundation for the Factory to advance towards mastering and producing modern, high-tech weapons and equipment.

Proud of its proven track record, the Factory will continue to uphold “proactivity, creativity, self-reliance, and self-strengthening”, overcome all difficulties, and strive to successfully accomplish all assigned tasks and truly deserve its position as a leading technical support facility of the Service and the entire VPA.

Sr. Col. TRAN VAN DUC

Factory Z119’s Director